Category I – Steel Innovation Center

The global pandemic disrupted construction and illustrated many of the AEC industry’s inefficiencies, redundancies, and limitations. This project is for the design of a new, national steel construction innovation center, to be located in the heart of the mid-West, where members of the AEC could research, exhibit, integrate, and teach construction innovations. Explorations at the steel innovation center could include: how to incorporate digital tools such as CAD/CAM processes, robotics, BIM, paperless delivery methods, virtual and augmented reality, and AI? How might steel construction add to sustainability discussions such as future proofing, climate resilience, energy performance, embodied carbon and energy of building materials, and energy generation? How might our buildings ensure the health and wellness of their occupants? How to integrate new building materials and details, assembly techniques, and construction methods?

Steel is an ideal structural system for this building. It allows for large openings, sunlight and easy airflow, flexible layouts, and innovative approaches to services. Steel can be easily modified during the life cycle of a building to accommodate changing requirements. This competition asks students to consider how steel can be used in a resilient manner for a center focused on innovation for the steel and construction industry.

Program

The Steel Innovation Center is to support a wide range of functions and users. Its primary purpose is to provide hands-on opportunities for full scale construction steel research and training. Large vehicles, trailers, and construction equipment should be able to fully access the fabrication and training spaces. Building users will include researchers, staff, teachers, trainees, tour groups, and interested public. A small daycare is to provide on-site support for staff and students. Daycare access is a primary stumbling block for people entering the training program. The building should balance the need for construction equipment access and circulation with safety for the public and daycare children.

Construction Type

The project must be conceived in structural steel construction and must contain at least one space/element that requires long-span steel structure, with special emphasis placed on innovation in steel design. The most compelling proposals will inevitably integrate the use of steel into the design of the project at multiple levels, from primary structure to building envelope and tectonic details.

Code

Refer to the International Building Code and the local zoning ordinance for information on parking requirements, height restrictions, setbacks, easements, flood, egress and fire containment. All proposals must be designed to meet requirements for accessibility; for guidelines, refer to the Americans with Disabilities Act and the principles of Universal Design.

The following is a list of programmatic spaces that must be included in the building. Solutions should observe the given spaces and sizes within a range of plus or minus ten percent.

Community Area

INDIVIDUAL SQ. FT. | QUANTITY | TOTAL | |

Community Exhibit/Entertainment Area | 5,000 sq. ft. | ||

Community Lobby and Reception | 1,000 sq. ft. | ||

Public Restrooms | 2,000 sq. ft. | ||

Services at 20% | 1,600 sq. ft. | ||

COMMUNITY AREA SUBTOTAL | 9,600 sq. ft. |

Innovation Fabrication

INDIVIDUAL SQ. FT. | QUANTITY | TOTAL | |

Open Bays | 14,400 sq. ft. | 3 | 43,200 sq. ft. |

Interior Loading/Unloading | 3,000 sq. ft. | ||

Workshop/Laboratory Areas | 5,000 sq. ft. | 4 (minimum) | 20,000 sq. ft. |

Two Locker Areas | 500 sq. ft. each | 2 | 1,000 sq. ft. |

Services at 10% | 6,720 sq. ft. | ||

INTERIOR FABRICATION SUBTOTAL | 73,920 sq. ft. | ||

|

|

|

|

Exterior Yard | 40,000 sq. ft. |

Classrooms and Offices

INDIVIDUAL SQ. FT. | QUANTITY | TOTAL | |

Training Room | 10,000 sq. ft. | ||

Classrooms | 600 sq. ft. | 4 | 2,400 sq. ft. |

Offices | 120 sq. ft. | 6 | 720 sq. ft. |

Copy Room | 120 sq. ft. | ||

Storage Room | 120 sq. ft. | ||

Lunchroom | 400 sq. ft. | ||

Locker Areas | 250 sq. ft. | 2 | 500 sq. ft. |

Daycare Spaces | 1,500 sq. ft. | 2 | 3,000 sq. ft. |

Daycare Bathroom | 500 sq. ft. | ||

Daycare Drop-off Area | |||

Protected Exterior Play | 1000 sq. ft. | ||

Services at 20% | 3,552 sq. ft. | ||

CLASSROOMS AND OFFICE SUBTOTAL | 21,312 sq. ft. |

BUIILDING TOTAL | 104,832 sq. ft. |

Additional Program Considerations

Consider daylight, security and safety for the daycare, connection to the exterior areas, and resilience for the facility spaces and equipment.

- Site Spaces and Requirements

- Parking for 40 cars

- Parking for 10 visitor cars and a school bus

- Daycare Drop-off

- Exterior Daycare Play Area

- Fabrication Yard

- Loading Area

Site

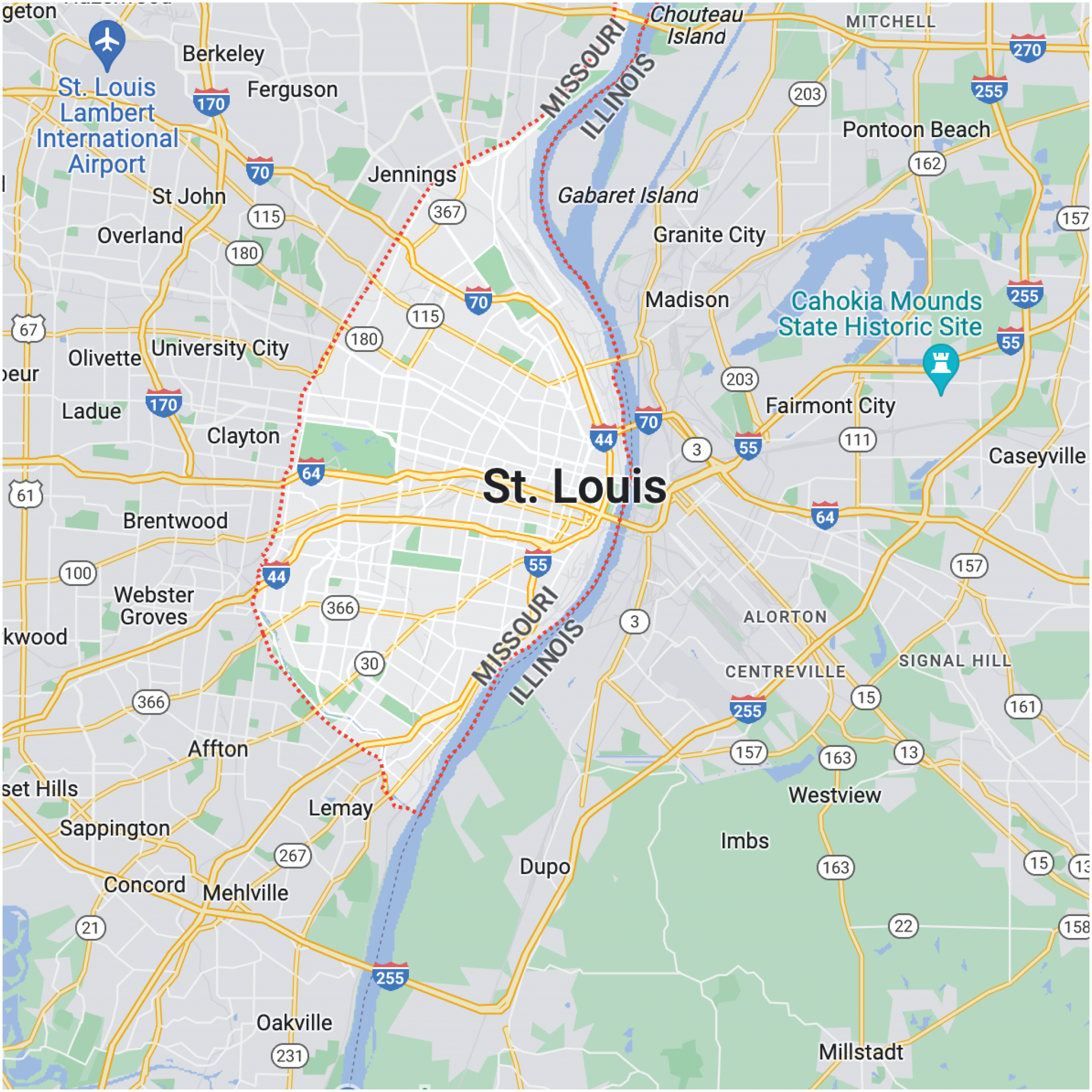

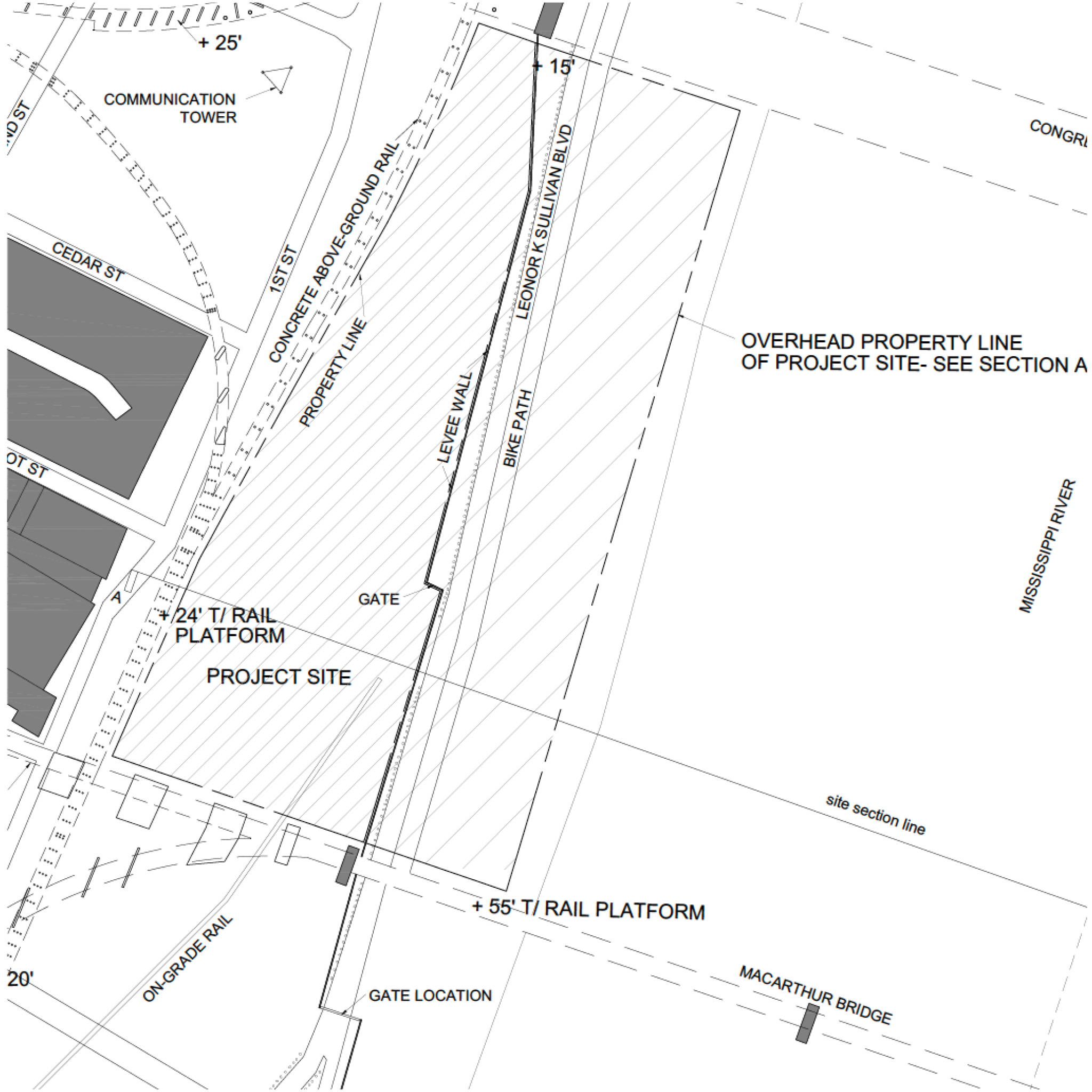

The site is in St. Louis, MO along the Mississippi River just to the south of the Gateway Arch and is part of the city’s future development of Gateway South. It is a wedge-shaped lot bounded the river’s levee wall on the east, the highway overpass on the north, the elevated rail lines to the west, and the elevated steel lines and MacArthur Bridge to the south. All permanently occupied spaces with equipment must be located west or above the levee wall to minimize flood damage from the River. It is possible, but not required, to cantilever or span over the levee wall up to the property line indicated. The area is located within a flood zone and flood resilience must be maintained, however the levee wall, also known as the Mural Mile, can be reconfigured or moved away from the River, or made taller if desired. The site is highly visible from Congressman William L. Clay, Sr. Bridge, or I-55/I-64. The MacArthur Bridge only serves rail traffic.

Access to the site should include pedestrian, bicycles, cars, large 18-wheeler trucks, and construction vehicles such as concrete trucks, boom cranes, fork lifts. The site is fairly flat. The site’s interior topography can be manipulated, but must meet the existing street grading and maintain flood resilience.

Gateway South Development

The project is just south of the Arch, part of the Construction Innovation District & Master Development in Downtown St. Louis, MO, and is conceived of as a construction capital or hub. According to Good Developments Group, the owner and developer of the innovation district, the area to be renovated and revitalized is “dedicated to the improvement of the design and construction industry through the use of advanced sustainable manufacturing technologies and the co-location of industry innovators.” The neighboring existing masonry warehouses and former manufacturing buildings are to be renovated and reimagined. The district will have a variety of uses, including manufacturing, workforce training, housing, and entertainment. Solutions for this project should communicate the spirit of Gateway South’s technology, integration, community, and innovation.

Note: We strongly discourage student visits to the site; the area is currently unmonitored and access could be restricted.

Performance Evaluation (For Category I only. Not required for Category II.)

Each student will answer a few multiple-choice questions upon submission about a performance analysis topic determined by the faculty or student(s). If possible, please show your performance evaluations on your submission boards and images. For the list of questions and an expanded explanation of this, please refer to the Supplemental Studio Guide and these questions:

- What category of performance did you measure or assess in your design?

- What standard or benchmark did you measure against?

- How did your final design performance compare with your standard or benchmark?

- If you measured and your design performance was below the standard or benchmark, did you redesign and measure or assess again?

Category II – OPEN

The ACSA/AISC 2024 Steel Design Student Competition also offers architecture students the opportunity to participate in an open competition with limited restrictions. With the approval of a sponsoring faculty member, students may select a site and building program.

The Category II program should be of equal complexity as the Category I program. Students entering Category II must submit a written building program, including a brief description of the building type, gross square footage, and project location, as part of the online submission in the Program Edits (copy/paste text box).

Restrictions

To enter the open competition students may select any building occupancy other than an innovation or museum building.

Construction

The design project must be conceived in structural steel construction and must contain at least one space/element that requires long-span steel structure, with special emphasis placed on innovation in steel design. The most compelling proposals will inevitably integrate the use of steel into the design of the project at multiple levels, from primary structure to building envelope and tectonic details.

Competition Organizers & Sponsors

Questions

Edwin Hernández

Programs Coordinator

ehernandez@acsa-arch.org

202.785.2324

Eric W. Ellis

Senior Director of Operations and Programs

eellis@acsa-arch.org

202-785-2324

Study Architecture

Study Architecture  ProPEL

ProPEL